On Saturday 15th April 2023 two tours of the Laubergast Shipyard near Dresden were offered with the first setting off from Dresden aboard the PS Pillnitz shortly before 10am. A second was offered in the afternoon at 2pm. The fare was set at 31 Euros. There were about 100 aboard on each trip thereby bringing in over 6,000 Euros that day in additional income for the company plus catering for the two short trips.

All ashore that’s going ashore at Laubergast.

There were two paddle steamers out of the water at the yard that day Diesbar (left) and Meissen. As you can see in common with many European river yards the ships are hauled out sideways.

This requires a series of winch engines to haul each of the cradles on which the ship sits up the slipway sideways at exactly the same rate. When in place the ship’s hull is then supported in multiple places by large steel blocks inserted underneath which have wooden wedges knocked in with mallets between them and the ship’s hull thereby providing the final adjustments to give maximum support throughout the length of the ship.

The river water level can vary by as much as 5m at Dresden making it impossible for the paddle steamers to pass under the bridges even with their funnels and masts down when it is high. And when it is very low there is insufficient water to float them so they were all built with incredibly shallow drafts to extend their operational window as much as possible. Look at the man standing beside the hull. All that is beneath the water level and the bottom of these paddle steamers is the distance from his chest to the top of his head.

When the fleet of nine paddle steamers was rebuilt in the 1990s after the Wall came down they were all fitted with bow thrusts to help them to turn round short in the narrow river. Previously they had conducted such manoeuvres with long wooden canting poles which were labour intensive requiring a crew member to do it. Now the captain does it himself by pressing the bow thrust controls and so helping to keep the operating costs down.

The paddle wheels are all of the feathering kind.

Another view of Meissen’s starboard paddle wheel showing on the right the eccentric mechanism for controlling the feathering of the paddle blades fitted on the inboard side of the paddle box.

The rudders are all super long to improve manoeuvrability.

The rudder stock enters the hull through a hole leading into a small watertight chamber above.

A mannequin dressed in an Elbe steamer’s captain’s uniform welcomed the groups into the workshops.

The woodwork shop with replacement decking in the background.

The metal workshop with important bits of spare steam kit stacked up and a spare generator in the foreground.

Spare paddle blades stacked up.

Could this be the only swing in the world constructed by welding together two paddle blades?

Seagoing steamships generally recycle the boiler water. The used steam is cooled down to become hot water in the condenser and then pumped back into the boiler. On fresh water rivers and lakes that condensate is generally not pumped back into the boiler but is discharged overboard instead with fresh water being sucked in to replace it from the river or lake and then pumped into the boiler. On the Dresden paddle steamers the water is sucked in through these grilles cut in the ship’s bottom.

This fresh water then passes upwards through pipes over which the hot condensate is being discharged overboard providing a sort of heat exchange to warm up the incoming water before it is pumped into the boiler.

All the Dresden paddle steamer have been rebuilt several times during their their long careers. Here is a picture of Meissen, built in 1885, towards the start of her career at a time when she was named Konig Albert.

Here you can see a combination of older rivetted hull plates on the left with newer welded steel plates on the right.

Stadt Wehlen berthed astern of Pillnitz at the Laubergast yard.

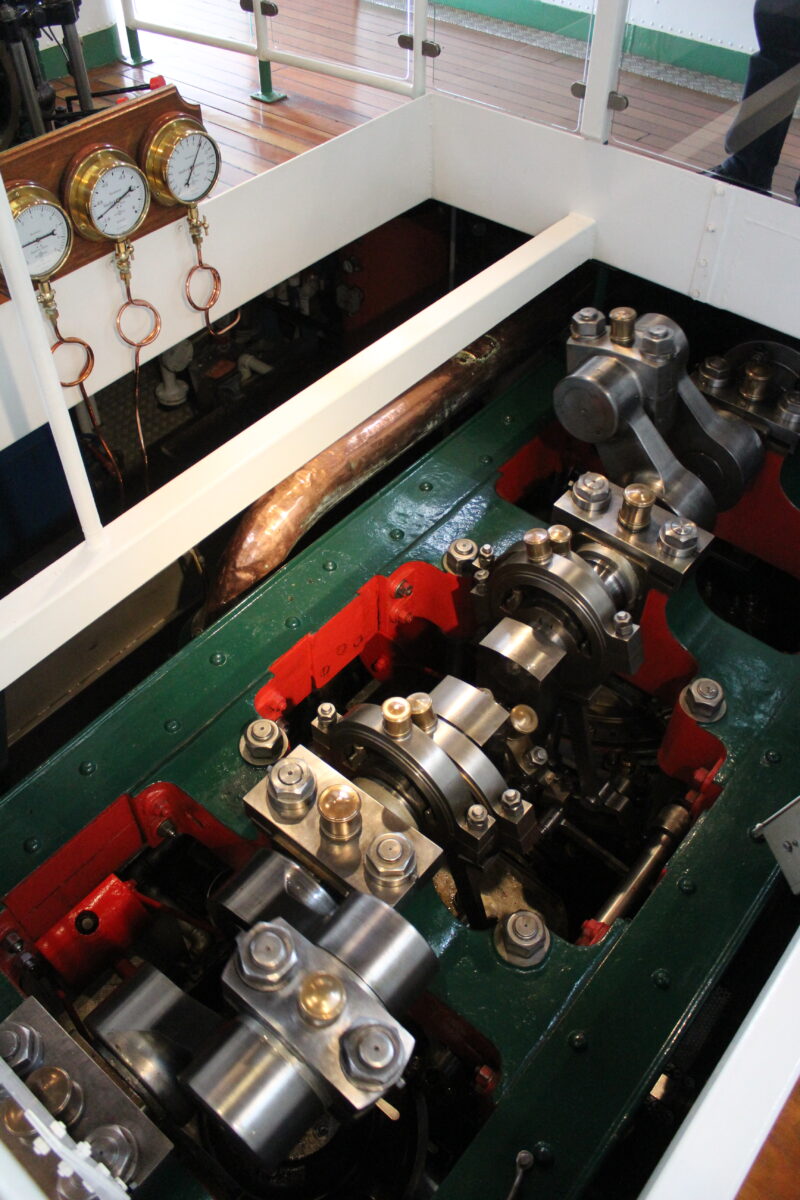

The oscillating steam engine of PS Kurort Rathen. The three gauges show from left to right the vacuum needed to suck the used steam out of the low pressure cylinder; the compound gauge showing either a positive or negative pressure in the low pressure cylinder with the one on the right for the boiler pressure.

Ships are generally required to keep to the right and pass port to port or red to red. However on European rivers they have a “Blue Flag” procedure which takes precedence over that if wanted. If one vessel wishes to keep to the left and pass another vessel starboard to starboard or green to green, they hoist a blue flag in the form of a blue board with a white flashing light at its centre. If the oncoming vessel agrees it hoists its blue flag and they pass green to green. It is a very useful procedure. Sometimes a vessel might want to be on the “wrong” side of a river for example for berthing. And sometimes on bends it is advantageous for vessels to pass like this taking advantage of the vagaries of the local currents in different parts of the river. Despite the usefulness of this procedure and its very successful operation on the continent it is not permitted on UK rivers.

The captain’s controls on the port bridge wing of Kurort Rathen. There is an electric telegraph for the engine, an electric tiller in the centre so that the captain can steer the ship without the need for a separate helmsman and on the left are the six buttons for the bow thrust. This combination of modern technology with ships from yesteryear helps to keep the operating costs down and therefore the business model more sustainable for the longer term. Apart from the catering crew to provide the coffees, beers, sausages and potato salad, and despite being 180ft in length, today Kurort Rathen has an operating crew of just three, a captain, one boatman and one machinist. That’s it. That’s the way to do it to help ensure that the income exceeds the expenditure and the business stays financially solvent.

All aboard for the return trip to Dresden.

Pillnitz returning to Dresden after the afternoon run to the Laubergast Shipyard on 15th April. A very interesting and happy day amongst the repair, maintenance and rebuild facilities for largest paddle steamer fleet in the world.

As you all know we are currently in the process of giving KC a major rebuild at the Dartmouth shipyard. Much of the work is now complete with hull plates renewed as necessary throughout as well as the frames, stringers and keelson from the boiler room to the stern and from the engine room to the bow plus all the bulkheads throughout the ship all renewed plus a new steel strake below the deck from the engine room to the stern both sides. Also the decking from aft of the engine room to the stern has been renewed. KC will therefore emerge back into service this summer in much strengthened and renewed form.

For next winter we plan to renew the hull strake below the deck and all the decking from the engine room to the bow .

Ships are built for a design life of 25 to 30 years. This envelope can be pushed with careful maintenance but if you want to keep ships operational for longer than that then you need to spend money on them rebuilding them as necessary just like with the paddle steamers at Dresden and in Switzerland over the years to take just two examples.

We have the funding in place for the work to date but we need additional funds for the next phase so do please keep the donations coming in. We need your help to do this. Do donate if you can to help set KC up for the next 25 to 30 years.

Kingswear Castle returned to service in 2023 after the first part of a major rebuild which is designed to set her up for the next 25 years running on the River Dart. The Paddle Steamer Kingswear Castle Trust is now fund raising for the second phase of the rebuild. You can read more about the rebuilds and how you can help if you can here.

John Megoran