This autumn and in the run up to Christmas the newly rebuilt Lake Geneva paddle steamer Rhone has been running lunch cruises on Sundays from Lausanne Ouchy (12.30) to Pully (12.40), Lutry (12.48), Cully (13.03), Vevey Marche (13.30), Montreux (13.52), Villeneuve (14.07), Chateau de Chillon (14.18), Montreux (14.32), Vevey (14.55), Cully (15.20), Lutry (15,36), Pully (15.46) and Lausanne 15.58), This has usually been preceded each Sunday by Rhone making a double run on the ferry service leaving Lausanne at 09.25 and 11.00 to Evian across the water in France. A paddle steamer engaged on a regular ferry service in winter. That is pretty rare anywhere. And remember Rhone is powered by steam. The diesel electric paddler Vevey has also been in service on Fridays and Sundays running short trips and lunch cruises from Geneva. So that makes two paddle driven vessels in service on Lake Geneva this winter. Well done CGN I say.

Bow thrusts have been steadily fitted to the Lake Geneva paddle steamer fleet. Here leaving Lausanne Rhone’s bow thrust lifts her off the pier.

Sunday 11th December was a lovely, albeit chilly, day on the lake and Rhone carried a good load on her lunch cruise.

Indeed the dining facility on the promenade deck could not have accommodated more.

Looking forward on the promenade deck.

Although chilly it was warm enough for some to enjoy sitting out on deck.

The seasonally decorated companionway between the promenade and main decks

The Belle Epoque dining saloon was also pretty full

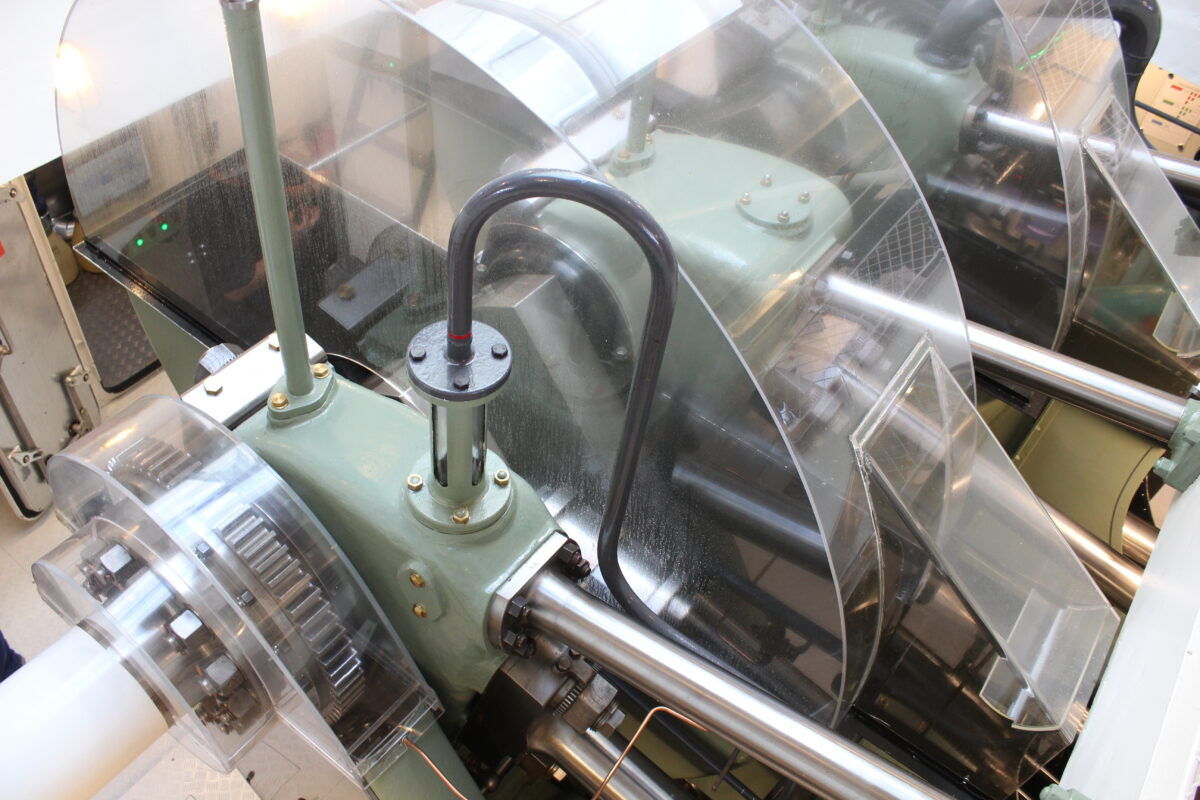

A good view of the engine

Rhone’s engine dating from 1927 has a pressurised lubricating system which requires the connecting rods to be covered by hoods to retain the oil. Originally made of steel they are now plastic so that passengers get a view of what is going on inside them.

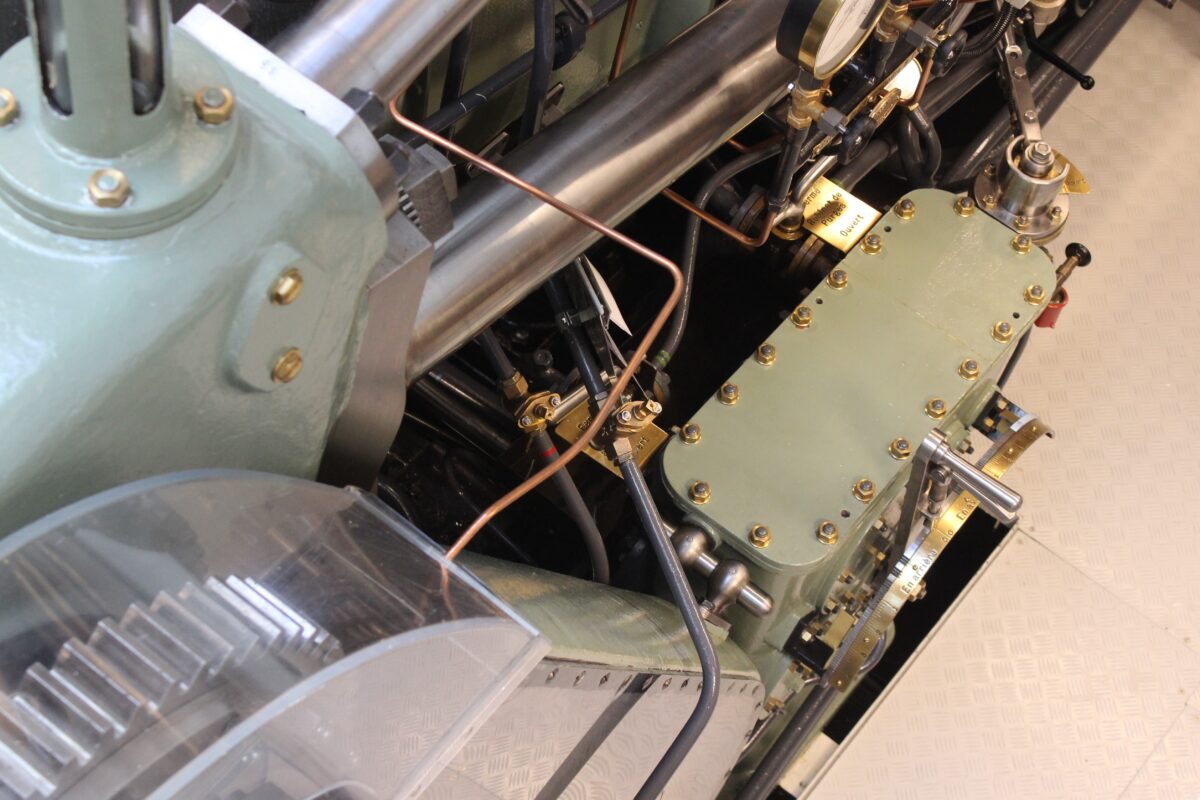

With a hydraulic mechanism to operate the valves for controlling the steam entering and leaving the cylinders the engine controls are much simpler on the Rhone than on conventional paddle steamer engines. The main lever in this picture controls both ahead and astern as well as the engine speed. The lever top right controls the exit of used boiler water overboard. Unlike sea going paddle steamers where the used steam as condensate is pumped back into the boiler on the Swiss steamers it is exhausted overboard with fresh lake water drawn in and fed into the boiler. So when the engine is stopped the water exit is turned off. And it is turned on again when the engine starts. The lever under the gauge opens and shuts drains,

Captains always try to prevent paddle steamers from landing heavily but sometimes it does happen. It sort of goes with the territory. The Swiss understand this so all their piers are bouncy to cushion any heavy landings. You can see in this picture that the piles around the end of the pier here at Pully are separate from the main structure of the pier, as they are on all the Swiss piers, so there is a lot of give in them. Years ago when Rochester Pier was being rebuilt by the Local Authority for KC’s use we incorporated a similar arrangement with the piles for that on which KC landed separated from the pier.

Despite their size, the Swiss paddle steamers do not use a windlass or capstan in the bow and stern to haul themselves alongside the piers. As the steamers come up to the piers the rope handlers lasso the piles. The captain leaves a tiny tad of astern momentum after stopping the ship which, when the rope is made fast, draws the steamers alongside the piers.

The crews are expert at lassoing the piles over quite large distances as you can see in this pic taken here at Cully.

The eccentric mechanism for controlling the feathering gear of paddle wheels is generally sited on the inboard side of the rubbing band within the paddle box slightly ahead of the line of the paddle shaft. So when a paddle steamer lands heavily on a pier, banging the rubbing band in the vicinity of the feathering mechanism may jiggle it a bit and maybe even knock its alignment ever so slightly out. This inevitably sets up stresses and strains within the paddle wheel and in extreme cases and with very heavy landings building up over time this may cause cracks and subsequent fractures in the driving rods and their connections within the paddle wheel.

Not only do the Swiss piers help to mitigate against that happening by being bouncy but also because the ends of the majority of piers (there are a few exceptions) are so short that the paddle steamers don’t land alongside piers in the vicinity of their feathering mechanisms thereby obviating heavy landings from jiggling them about. They land alongside the majority of piers with the loading gates either ahead of, or abaft, the paddle boxes. Neat really.

All the Swiss paddle steamers require only a one man bridge watch. The captains do their own steering either from within the wheelhouse or from jog switches on each of the bridge wings. That saves the costs of hiring a separate helmsman and that adds up over a season and throughout their fleets.

When chart plotters and other modern electronic kit started to come in the Swiss steamers were not in the forefront of fitting it. I recall years ago the Lake Lucerne captains wanted to have such things. The management resisted on the basis of cost. As a result all the captains got together and bought simple and cheap chart plotters which they fitted themselves. That reluctance has now long gone and all the Swiss paddle steamers bristle with modern electronic kit. Indeed some even have chart plotters in the engine room so that the engineer can keep tabs on where the ship is and see how long it will be before they arrive at the next pier.

Each of the Swiss paddle steamers do have a windlass in the bow for hauling up the anchor if ever it is dropped. But they are all hand operated and are never used for the usual berthing on and off piers.

And so ends a lovely day in December on a paddle steamer on Lake Geneva. Why not take a trip yourself? Rhone is currently rostered to continue these Sunday sailings for the rest of December, on into January and beyond. And at Geneva Vevey’s winter schedule is due to be taken over by her sister Italie from Sunday 18th December.

Switzerland is such a paddle steamer wonderland. Here in the Lausanne Ouchy shipyard on 12th December 2022 are six paddle steamers (the sixth is just out of shot on the left) with two more at Geneva. And they rebuild them every thirty or so years to keep them in service “for ever”. In the recent past here on Lake Geneva PS Vevey was rebuilt 2012/13, PS Italie 2015/16 and PS Rhone 2019/22. That’s the way to do it. That’s the way to keep paddle steamers in service long term.

That’s therefore the template which we are using for KC’s rebuild. Strip back to remove rotten wood and corroded steelwork. Then renew. We have the funding in place for the first phase of KC’s rebuild this winter but we are still seeking funding for completion of the work in the next two winters. Do help if you can. All donations will be very gratefully received. And if you like you can have your name added to our donor wall.

Kingswear Castle returned to service in 2023 after the first part of a major rebuild which is designed to set her up for the next 25 years running on the River Dart. The Paddle Steamer Kingswear Castle Trust is now fund raising for the second phase of the rebuild. You can read more about the rebuilds and how you can help if you can here.

John Megoran