On Tuesday 6th March 2001 Kingswear Castle’s new boiler arrived from the factory of Wellman Robey and was lifted into place aboard the ship.

The new and the old boilers next to each other in the Acorn Shipyard at Strood. They were identical in pretty much every detail with the exception that the new was all welded where the old had been built with a mixture of rivets and welding. Both had traditional domed endplates which we felt have the capacity to extend the lifetime of a boiler. We also felt it would be nice to bring a little bit of the old across to the new so the furnace door from the old, which was still in fine condition, was transferred to the new.

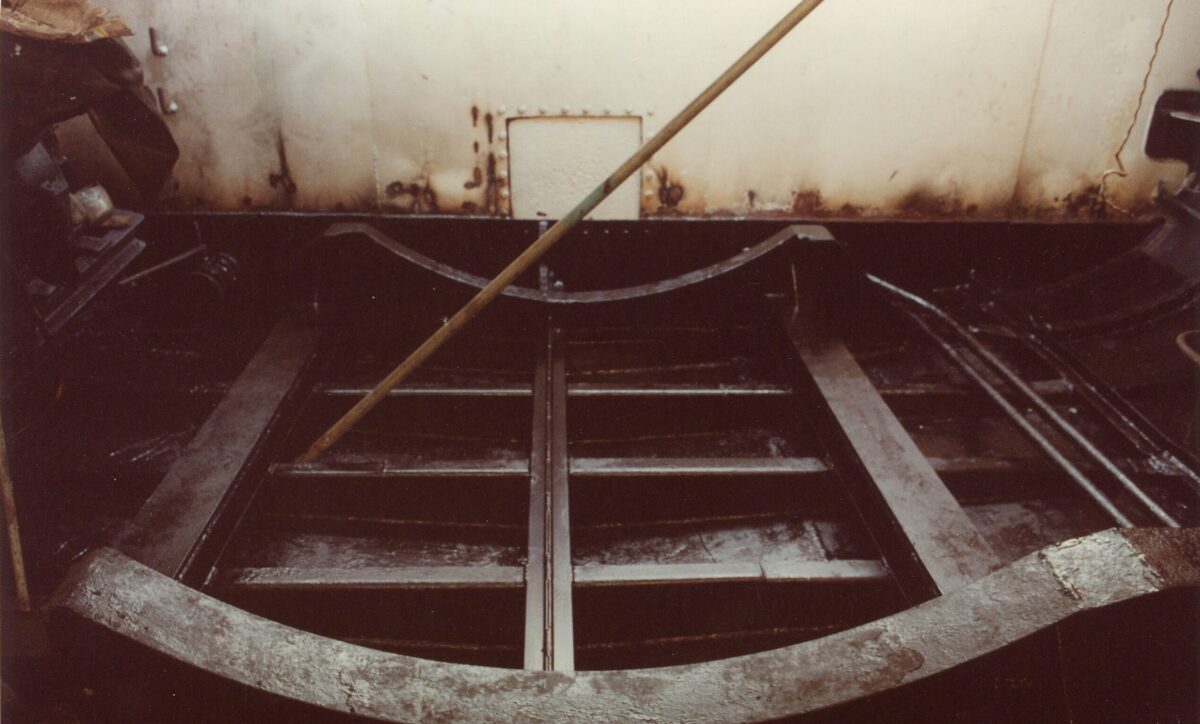

Some work had been done on the boiler cradles to make them fit to receive the new boiler. In ships boilers are not bolted down because of the issues that would cause with expansion. Instead they lie in their cradles with chocks at either end to prevent them sliding about.

In the middle of the afternoon the boiler was lifted aboard and lowered into place. On the left is our then engineering trustee the late Alan Beavan OBE. He had a chief engineer’s ticket and had a life time’s experience behind him at sea, as a shipyard manager and marine superintendent. There was therefore nothing Alan didn’t know about ships, engines and the inner workings of shipyards and manufacturers. He was also a dab hand at drawing up contracts with manufacturers and shipyards so as to avoid later fallings out when one party thought that something should have been done which the other party didn’t believe that they had been contracted to do. Alan was such a help to me and became a very good friend as well.

We were very pleased with the new boiler. It worked well, produced the right amount of steam and was easy to handle and damp down when needed in service.

It is now nearly twenty years old and the only issue we have had with it was the discovery of some cracks near the furnace front three years ago. These are quite common in this sort of boiler but do have the capacity to alarm present day MCA surveyors who may not have a lot of experience of this sort of plant.

There are two way to address this. A hole can be cut in the boiler and new plate inserted and welded into place. The advice we had when this happened to the old boiler was that doing it that way is best avoided if at all possible as it tends to shorten a boiler’s life by introducing new stresses into a boiler’s structure which cannot easily be annealed out. The alternative way, which was recommended to us by our friends at Babcock who are dealing with this sort of thing all the time on a day to day basis, was to grind out the cracks, butter them up with new weld, buff off and then take ultra-sonic readings afterwards to check that all is OK. So this is what we successfully did at different times on both boilers.

Kingswear Castle returned to service in 2023 after the first part of a major rebuild which is designed to set her up for the next 25 years running on the River Dart. The Paddle Steamer Kingswear Castle Trust is now fund raising for the second phase of the rebuild. You can read more about the rebuilds and how you can help if you can here.

John Megoran

This article was first published on 6th March 2021.